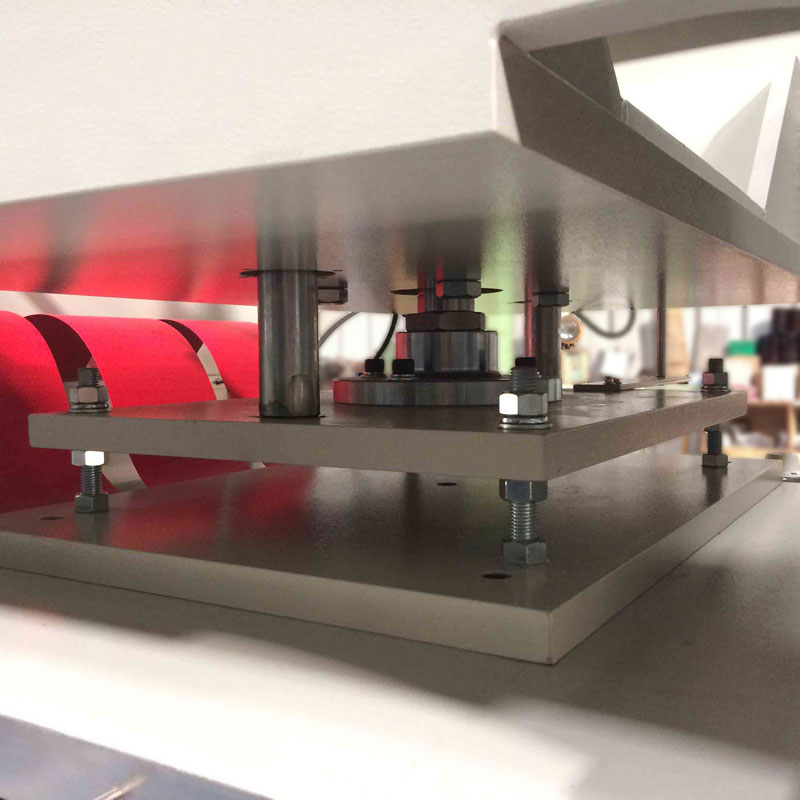

Shuttle Tray type is equipped with sliding trays that can weld the products in turn. It depends on customers' demands; different molds can be placed on the electrode above. Because of the overhead electrode, operators can promptly orient the position of products to eliminate the risk of errors. It has a large tray space that can make it easy for operators to change products; hence it will increase the working efficiency. The operational method is to adopt sliding table for feeding. It increases the protection for operators. The accuracy of in and out of sliding table is high. The speed is fast and the thickness can be adjusted according to product area.

High Frequency Welding Machine – Shuttle Tray type

Protection has been improved to better protect the operators. These slides out trays operate with high speed, high efficiency and high accuracy. Shuttle Tray type is suitable for customers who need mass production. High Frequency Welding Sliding Tray Type can be used to weld synthetic leather products containing PVC more than 30%, and other PU, Nylon, EVA, PEVA, PET, PETG etc. Shuttle Tray type can be used in various fields such as manufacturing of car bench layers, raincoats, umbrellas, footwear, logo printing, medical treatment bags, inflatable products, blister and curtains etc. Shuttle Tray type is a good choice for customers who demand work efficiency.